The decision to build the plant was made in 1936 by the Military Council of the Automotive-Armored Directorate of the Red Army.

The plant was named Repair Base No. 77 and a construction site was chosen in the Russian Far East in Ussuriysk, which used to be called Voroshilov between 1935 and 1957.

The design of the plant was first developed by the Leningrad Design Institute Spetsproekt, and then Voenproekt of the Military Construction Department finalized the project based on the calculations and schemes provided by Spetsproekt.

The first cubic yards of concrete for the foundations were laid in 1937.

The plant was to have five workshops: a dismantling and assembly workshop, a mechanical workshop, a motor-aggregate workshop, an electrical workshop, and a mechanical repair workshop.

In March 1940, the main construction works of building A were completed. The building was to be for the dismantling and assembly of tanks, tractors, and tank engines.

While equipment was being installed, building A received its first batch of tanks and tractors.

On May 12, 1940, the plant was officially opened. By this time, five tanks and two tractors had already been repaired.

The opening ceremony was grand and festive, with an orchestra playing and a demonstration of the seven repaired vehicles. The commander of the 1st Special Red Banner Army Corps, Commander Markian Popov, cut the ribbon.

In 1946, the plant was renamed the 229th Repair Base.

There was a common misconception among leaders in the Automotive-Armored Directorate, engineering specialists, and heads of departments that the plant was merely a marginal industry.

This thought was largely due to its remote location. Moscow officials did not visit the site because the train journey from Moscow took eleven days.

They had no idea about the plant’s real capabilities and even appearance.

In 1948, a direct plane link between Moscow and Vladivostok, a major city in the region, was established.

Even though it still took up to three days and had one and sometimes two overnight stays, it made the journey much easier.

In summer 1949, the head of one of the departments, engineer-colonel Sivkov; and deputy head of another department, engineer-colonel Balashov, arrived.

They spent a month at the repair base and realized that it was not some minor enterprise but rather a large and modern plant that was capable of solving even the most difficult repair tasks.

This visit had a huge impact on the future of the plant. The repair base was one of three plants in the whole of the USSR that were entrusted with the task of modernizing heavy tanks from the IS series.

It modernized IS tanks for all armored forces located east of the Ural Mountains.

A curious incident is associated with this upgrade. The floors of assembly shop no. 1 were originally intended for light tanks.

As heavy tanks weighing 30-40 tons were brought here for repair, the floor quickly collapsed.

The floors were expensive to replace because rare types of hardwood were required, so metal floors were built instead. They were built using recycled metal from parts of T-34 tanks.

In 1953, the repair base was renamed once again. It became the 206th Armored Repair Plant.

From March 1959 to May 1965, the plant mastered the repair of T-54, T-55, T-62 and PT-76 tanks as well as BTR-50 amphibious vehicles.

In the 1960s and 1970s, new buildings for industrial and domestic purposes were built. The new facilities included a brick garage for forty cars, a compressor station, a treatment plant, a production building, and a kindergarten for workers’ children.

From May 1976 to September 1981, Colonel Alexander Bubis was appointed the head of the plant. During this period, the plant began to master the repair of BMP-1 amphibious vehicles.

For five years, the plant underwent great developments. These included improvements in construction methods and the organization of labor, expanding capacities, and the introduction of the latest achievements of scientific and technological progress.

Medical care and social conditions were also improved. On November 15, 1979, the plant was awarded the prestigious title of an “Enterprise of high production culture.”

In the 1980s, new housing for employees and workers was constructed, as well as a few new production buildings and access roads. The plant started repairing T-80B and armored vehicles BTS-2 and BTS-4.

After the USSR collapsed, the plant carried on operating, although its importance began to decline. In 2009, it was transformed into an open joint-stock company called the “206th Armored Repair Plant.”

The company went bankrupt. Some premises were sold and are now private property.

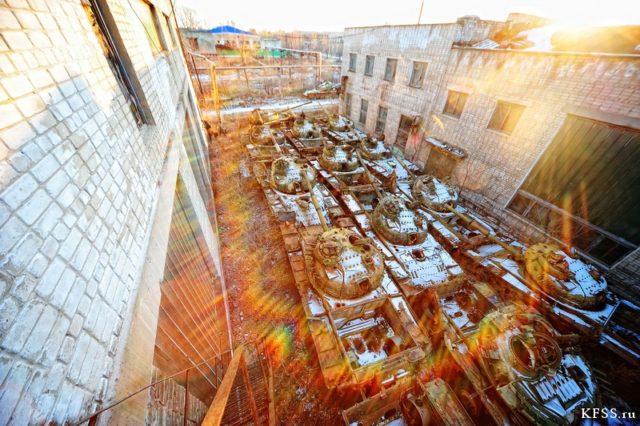

A huge number of dismantled tanks were left behind and were slowly dismantled by metal hunters. Rusted caterpillars and broken tank towers remain scattered throughout the territory.

A big thank you to KFSS for the photos and information! See more of their work here: KFSS

Also a big thank you to Mikhail Simanchuk for his photos! See more of his work here: mikesiman