The Wagner Manufacturing Company that became such a cornerstone of Sidney, Ohio, all started with a German immigrant named Matthias Wagner, who moved to the United States in 1838 and began working on the Shelby County Canal.

The work was hard and the pay was low at only $1 an hour, so Matthias tried his hand at raising cattle and hogs.

A savvy businessman, he soon realized that Sidney was growing rapidly, so he made some smart real estate investments and soon became the wealthiest man in town.

In 1863, he added a hotel to his entrepreneurial list. The hotel was the best around and even boasted a ballroom on the third floor.

Wagner and his wife Mary Routh raised 12 children. However, two of Wagner’s sons, Milton and Bernard, did not want to follow in their father’s footsteps.

Instead, they wanted to create their own manufacturing company. So, in 1890, construction work began on a new factory at 440 Fair Road, Sidney. This would become known as the Wagner Ware building.

The project was under the direction and supervision of architect Joseph Altenbach. Not only was Joseph known for his work on many large buildings in the city, but he was also a good friend of the family.

In 1891, Louis and William Wagner joined their brothers and incorporated the Wagner Manufacturing Company. RO Bingham joined the company as superintendent due to his experience working at the Marion Stove Works and the Sidney Manufacturing Company.

Wagner Manufacturing Company began producing cookware. Initially, it produced standard cast iron products, but in 1892, it added nickel-plated items to its production line.

In 1894, the company became the first of its kind to manufacture cast aluminum cookware such as casserole dishes, baking trays, and kettles.

Business was booming, and the Wagner company became such an important producer of iron and aluminum products that it ended up dominating the cookware market with a 60% share. It also won several international awards.

The company also began to diversify. As well as cookware, items such as furnace grates and rubbish burners were added to the ever-expanding inventory. The company’s products became very popular and consequently were sold not only in the United States but also in Europe from 1913.

However, even the prosperous Wagner company did not escape the effects of the Great but began to see falling sales during that period. In an effort to revitalize business, the company recruited John Gordon Rideout to redesign their products.

Together with Harold Van Doren, Rideout designed two Magnalite products: a kettle with varying thickness to heat the water evenly and a covered casserole dish. This line has grown to be huge, and Magnalite products are still produced today.

In the 1940s, the company was owned by the heirs of the founding brothers. From 1946 onwards, the owners started divesting themselves of their shares, so the company was no longer a family-run business.

Instead, the company passed through various hands until it ended up being owned by American Culinary, a company that continues to produce Wagner products today.

Nowadays, Wagner products are highly valued items to collectors, especially the cast iron skillets and dutch ovens, as well as the original Magnalite range that Rideout and Van Doren designed.

All Wagner products have the name Wagner and “Sidney, Ohio” stamped on their base because the brothers wanted to put their hometown on the world map.

However, despite the popularity of the range, production was moved away from the Wagner Ware factory in Sidney.

The land passed through several owners until it was permanently closed in 2008. By then, it was owned by Master Vision Polishing. After a wall fell down, all the buildings on the site were deemed too hazardous for the workers inside.

After the factory was abandoned, Master Vision Polishing did nothing to maintain the site, and the neglected state of the buildings was a great headache to Sidney officials.

The cost of demolishing the buildings could be up to $1.5 million, while an extra $350,000-600,000 would need to be spent on soil remediation to make the site usable.

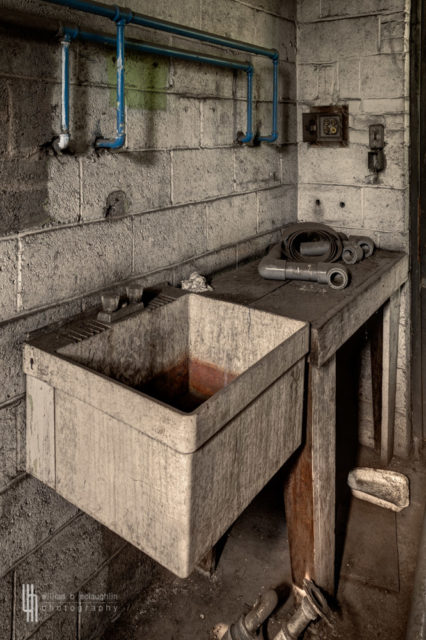

Visitors to the Wagner Ware factory will likely find a boarded-up building wrapped in security tape. Those who do manage to get inside will likely be met by disintegrating floors.

However, with a security system in place that alerts the police to any intruders, even seasoned urban explorers would be wise to give this place a miss.

In 2018, a group of urban explorers managed to access the building and posted a YouTube video about their visit, prompting police to try and track them down and prosecute them for criminal trespassing.

The police chief said the trespassers were not just putting themselves in danger, they were also risking the lives of any first responders who might be called to the site.

In December 2019, the Wagner Ware building was in the news once again when part of it collapsed on Christmas Day. News reports said Master Vision Polishing was going to be invoiced for the clear-up work and the emergency demolition of part of the building that was necessary in the wake of the accident.

William McLaughlin kindly granted us permission to use his photographs of the abandoned Wagner Ware building. He is a photographer who specializes in exterior and interior shots of abandoned buildings.

William describes how his hobby has brought him to have a passion for industrial architecture and old mechanisms often concealed inside. You can check out his abandonment photography on his website, as well as his photographs of macro objects, severe weather events, and indoor sports like table tennis on his Flickr account.

Craco – Medieval Ghost Town in Italy