It was to be situated between Charlestown and Jeffersonville, Indiana. After the first National Defense Appropriations Act was passed in the United States, the construction of the largest smokeless powder plant in the world was officially announced.

It was common practice that such plants should be located close to water and the Ohio River, which ran nearby, made it possible to obtain the water needed for production.

This site was also chosen because it was not densely populated due to the fact that the surrounding land was not suitable for agriculture. As well as being a safety feature, this also meant that the land was cheap to buy.

Construction of the plant began on August 26, 1940. At that time, Charlestown was a small market town. But after the factory was announced, about 13,000 workers from all over the country moved to this place seeking employment.

In Charlestown, things changed dramatically. The schools became overcrowded, street markets popped up, and there was a steep hike in prices for the purchase of the surrounding land and the rental of existing rooms.

In the spring of 1941, about 800 buildings were constructed. The site eventually covered about 19,000 acres with 1,400 buildings, making the Indiana munitions plant the largest in the country.

The plant consisted of three zones of production. The first zone was called Indiana Ordnance Works Plant 1 (IOW 1), the second one was IOW 2, and the third one was Hoosier Ordnance Plant (HOP). Although initially three separate enterprises, the three zones were merged into a single entity in November 1945.

IOW1 manufactured smokeless and black powder. Construction began in August 1940 and was finally completed only in May 1942 at a cost of 75 million US dollars. Smokeless powder (nitrocellulose) was designed to be used as fuel for a projectile, while the black powder was there to ignite the smokeless powder.

This zone consisted of 800 buildings divided into four areas. One area dealt with the production of smokeless powder while another area handed the storage and shipment of the product. There was also an administration section with a hospital, a cafeteria, and security headquarters, and River Ridge was a residential area designed to house senior officials.

In IOW1, about 25 percent of the workers were women.

During the Second World War, the plant produced more smokeless powder than any other plant had produced during the entirety of the First World War. This zone was ultimately shut down after the end of the war on September 7, 1945.

IOW2 produced double-base rocket fuel. The construction of the plant began in late 1944 but was never completed, since Japan surrendered in August 1945. However, sub-production did take place at the unfinished plant from July to August 1945.

German prisoners of war, who were used as unskilled labor throughout the plant, were housed in this section. During the short time it was operating, IOW2 produced about 300,000 pounds of gunpowder.

On February 11, 1946, IOW2 was put into standby mode, but production would never be resumed there. Instead, in 1960, all the stored powder was removed and the land was given over to be used as woodland.

The construction of the HOP, which would produce bagged powder for cannons and mortars, began in January 1941 and was completed in February 1942. The total cost of construction exceeded approximately 28 million US dollars.

The plant was engaged in producing special bags to package the smokeless powder produced in IOW1. The powder would be sewn into the bags which were then packed into containers. After that, they would be shipped off or stored in a warehouse.

About 65 percent of the workers in the HOP were women. On August 18, 1945, the plant ceased production for a while until 1950.

It is a fact that if munitions factories are not properly constructed or operated efficiently, there is a chance that a massive explosion could occur. With this in mind, the buildings were built quite far apart from each other to limit any damage should the worst happen.

In addition, smokeless powder was transported via copper-lined chutes which would reduce the amount of powder sent up into the air. Workers also had conductive shoes to reduce static electricity and in some buildings, emergency slides were installed to provide workers with a quick escape if necessary.

Unfortunately, despite such measures, a powder magazine area designated Igloo 5185 Q was destroyed by an explosion in 1966.

Under War Department Circular No. 329, the three plants were combined into one known as the Indiana Arsenal on November 30, 1945.

The Korean, Vietnamese, and Cold Wars allowed the partial and temporary resumption of production at the Indiana plant. During the Korean War, 50 new buildings for storage and maintenance were built on the site.

In 1963, the Army’s General Order No. 35 gave the plant its official name which has carried on to this day: the Indiana Army Ammunition Plant.

During the Cold War, the federal government built new facilities, including the Black Powder Manufacturing Facility designed to limit personnel exposure to black powder.

With these new structures, the design team addressed and eliminated problems that had cropped up in the transportation and humidity control system as well as the grounding system of the power grid.

In March 1983, the plant produced 2,200 pounds of black powder. In total, about 3.2 billion pounds of black powder was produced during the entire operating life of the plant.

Several attempts were made to update the plant with new features. For example, between 1988 and 1989, INAAP sought funding from a private corporation to operate the plant and produce black powder for another 20-25 years. However, this was unsuccessful.

Gradually, more modern plants began to appear throughout the country and the Indiana plant became outdated. In the spring of 1989, about a third of all the workers were laid off after the plant failed to secure two lucrative contracts.

However, two final orders were placed, which delayed the closing date until October 1992, when these orders had been completed. At that time, only 750 people were employed there.

In 1995, an environmental study was carried out near the former ammunition plant and 87 areas were identified as being contaminated by pollution with another 53 areas being listed as having pollution issues.

A sum of 33 million dollars was allocated to address this pollution and it was decided that more than 1,000 buildings would need to be demolished.

Demolition plans were drawn up for February 2004. Because many of the buildings contained gunpowder residue, it wasn’t possible to demolish them in the usual manner. Instead, they were set on fire at a time when the wind was from the west or southwest.

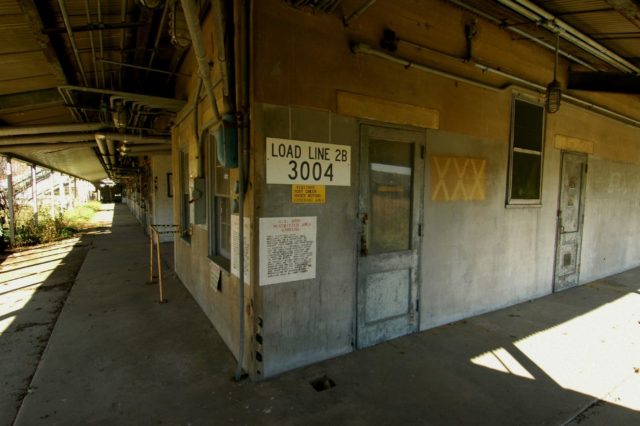

Today, much of the site remains abandoned, but part of it has been turned into a commercial center.

The photos of Indiana Army Ammunition Plant were taken by Donald Vish who is a lawyer, a poet, a photographer, and a teacher based in Harrods Creek, Kentucky. His amazing Flickr account has a wonderful variety of photos which you should definitely check out.

A huge thank you to Donald Vish for allowing us to use his photographs in order to share this story about an abandoned plant with our readers.

Another Article From Us: Abandoned Mansion of Alfred Nobel Creator of the Nobel Prize